Business

stagnationForeign companies are interested in manufacturing only non-competitive ag equipment in Ukraine

In mid-September the US Department of Agriculture (USDA) improved its forecast for the expected gross grain harvest in Ukraine by 2.5%, which is a bit more than 58.5 mn t (the USDA published its previous forecast at the beginning of the month). American experts calculated that wheat crops should be approximately 22 mn t (the forecast was upgraded by 1 mn t) and the harvest of forage crops (corn, barley, etc.) should be close to 36.51 mn t.

Earlier, Ukrhidrometeotsentr (Ukrainian Hydrometeorology Center) assumed that due to the weather conditions this summer and operational data on the state of the crops it can be predicted that the gross harvest of grains in the country this year could be much higher – at the level of 2013 (approximately 63 mn t). Experts say the dynamics of the gross harvesting of grains over the last few years (under different agro-meteorological conditions) allows for suggesting that achieving the annual rate of harvesting 70 mn t is no longer an impossible task for Ukraine. Furthermore, experts are convinced that last year Ukraine had 70 mn t in its fields, but the hopelessly outdated and obsolete fleet of harvesting equipment of domestic agricultural enterprises resulted in the situation when a part of the crops was left unharvested in the fields.

What we have

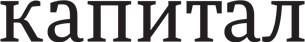

At present, there is no official data on the number of harvesters in Ukraine. The latest extensive research of the State Statistics Service on the availability of machines and mechanisms in the agricultural sector was conducted two years ago. At the beginning of 2012, Ukrainian enterprises had approximately 54,000 harvesters (since 2000 the fleet decreased by 20%), based on the obtained information. Today, taking into account the gradual breakdown and wear and tear of equipment and the reduction of both domestic production and imports over the last two years experts are cautiously assessing the size of the fleet at approximately 52,000 harvesters.

The problem is not the number of harvesting units, rather the condition of the available equipment, which discourages experts, to put it mildly. Head of the Analytical Department at ITT-Management Vitaliy Murashkin says the foundation of the fleet (up to 65% of the total amount of equipment) consists of physically and morally outdated combines with a capacity of up to 11 kg/s. In fact, 90% of the existing fleet should be replaced.

Taras Vysotskiy, Director of UKAB-Service (a division of the Ukrainian Agribusiness Club Association), drew similar conclusions. He says the ratio of harvesters bought over the past few years to bolster the existing fleet is approximately 5%. This indicates that on average in Ukraine harvesters are used for 20 years, while their optimum service life is 10 years. In addition, approximately 25% of the harvesters are already so obsolete that their immediate replacement or at least decommissioning is required, as it is dangerous to operate them. In other words, such equipment does more harm than good in the fields. It was the operation of totally “used-up” harvesters by Ukrainian agricultural enterprises that led to a shortage of nearly 5–6 mn t of crops last year (grains were either spilled on the fields or not threshed). In addition, in a number of cases the weak capacity of the outdated models of combines prevented them from reaping the full harvest in due time, which accounted for additional losses of crops (grains crumble in their ears).

In addition to the shortage of harvesting capacities, a sharp decline in sales was also observed this year on the agricultural machinery market, similar to that in the crisis year of 2009. The demand for combines will be 2.5 – 3 times lower compared with the previous year, according to estimates of member of the All-Ukrainian Agrarian Council Oleksiy Bondar.

What we need

Along with the poor technical condition of the combine fleet and a sharp reduction in sales of such equipment in Ukraine there is a clear shortage of harvesters in general (especially given the prospects of increasing gross harvesting of grains). As Agrarian Minister Ihor Shvaika stated at the beginning of the harvesting campaign in 2014 the average load per one harvester will be approximately 196 ha. The minister also added that for normal operation of the existing fleet this figure should not exceed 120 ha (in other words, the farmers have no other choice but to finish using the already obsolete equipment). However, attention is drawn to the fact that the greatest burden fell on harvesters used for cropping in the country’s main grain producing regions. For example, in the Mykolaiv and Odesa oblasts each harvester was assigned more than 250 ha, in Kherson – more than 270 ha and in the Zaporizhzhya oblast this figure exceeded the “ministerial” rate by almost 3 times – more than 300 ha per one unit of equipment.

At the same time, independent analysts believe that Shvaika is rather cunning in his assessment of performance standards. “Indeed, the load of a harvester in Ukraine is 200 – 400 ha and even more. Yet, in developed countries with their incomparably better condition of agricultural equipment the standard load on every combine is 70 ha,” said Murashkin.

There are official estimates of Ukraine's needs for agricultural machinery and equipment drafted by the Institute of Mechanization and Electrification of Agriculture National Scientific Center at the National Academy of Agrarian Sciences of Ukraine (NAASU). Taking into account the expected crop production the country’s general need for new combines is 65,000 units, according to scholars. Noteworthy, the NAAS believes Ukrainian farmers should buy 10,000 new combines with a capacity of more than 12 kg/s, 30,000 harvesters with a capacity of 10 – 12 kg/s, and 25,000 of the least powerful machines (with a capacity of up to 10 kg/s).

In general, analysts do not dispute the findings regarding the general needs of the agricultural sector for new technology developed by scientists, but they fundamentally disagree with the structure of the proposed renewal of the harvesting fleet (yet those are the conclusions drawn at the official level on which the investment policy of the state depends). However, the greatest load on harvesters is in the southern regions of Ukraine with large areas of plowing, which also provide the largest amounts of grains to the hutches of our homeland. It should be understood that an agrarian enterprise with large planting areas cannot increase its fleet of combines to infinity through procurement of inefficient models. Therefore, priority should be given to highly productive combines with maximum capacity.

CEO of the Kherson Machine-Building Plant LLC (KMBP) Oleksandr Oliynyk says it is quite effective to use combines with a capacity of up to 10 kg/s on small farms with up to 2,000 crop hectares and a crop yield of up to 40 t/ha. “But the farms in the steppe zone, whose area of plowing exceeds 2,000 ha and crop yield is more than 80 – 100 kg/ha, simply need harvesters with high output of more than 12 kg/s,” says Oliynyk.

Indeed, as Murashkin said, “only one of ten harvesters used by Ukrainian farms is highly efficient and has a capacity of more than 14 kg/s”. There is a suspicion that in the calculation of our country’s needs for agricultural equipment the NAASU simply extrapolated the already existing structure of the combine fleet, mostly inherited from the Soviet Union. It does not factor in changes in the realities of the domestic market, or the progress in the development of agricultural equipment and machinery.

What they want

In early September General Director of the Ordzhonikidze Kharkiv Tractor Plant (KTP) Vladyslav Hubin said the plant will set up a joint venture with the Belarusian holding company Gomselmash, which will focus on the assembly of grain harvesters using Belarusian components at the KTP. The plant has plans to produce prototypes of new products by the end of the year and start mass production (with a gradual increase of Ukrainian parts in harvesters) in 2015. For assembly the company chose Gomselmash’ Palesse GS12 (to be sold on the Ukrainian market under the KhTZ Palesse trademark).

Such a move on the part of the Kharkiv company should be welcomed, Bondar said, seeing as “Ukrainian enterprises producing self-propelled machines are hopelessly falling behind and will not be able to produce competitive agricultural products independently. There is a future for them only in cooperation with the world’s leading manufacturers”.

A similar view was expressed by Director of the Smart Queen Marketing Agency Natalya Tserkovnikova, who noted that CLAAS, John Deere and CNH harvesters are increasing their share on the Ukrainian market year to year. “It is difficult for Ukrainian manufacturers to resist their aggressive marketing budgets - they have the best trading companies at their service. But if we focus on agriculture, harvesters can and should be assembled in Ukraine. The domestic agro-industrial complex is not a closed cycle – engineering was withdrawn from it. And without this it will become a typical banana republic with our black earth,” complains Tserkovnikova.

By the way, in mid-August Shvaika, the heads of departments of the Ministry of Agrarian Policy met with representatives of the American Deere and Company (TM John Deere). The ministry tried to persuade the company to consider the possibility of production of modern agricultural machinery in Ukraine and implement joint investment projects to provide farmers with innovative technology. Judging by the absence of even so much as declarative statements of the Ministry of Agricultural Policy, the meeting gave no fruitful results.

It must be said that the plans of entrepreneurs and statements of officials regarding joint projects for the assembly of harvesters, unfortunately, evoke a déjà vu sensation. Just over a year ago, the press service of the CLAAS Group of Companies reported that the first JV for the assembly of combine harvesters commenced operation on the basis of the KMBP. At that time, there were plans to start deliveries of components for assembling CLAAS harvesters at the KMBP “in the earliest possible time”. Of course, it was referred to as the SKD assembly (actually, the CKD assembly), but it was expected that over time the number of parts and components produced in Ukraine would increase. It was expected that in the first year the company would produce 150 TUCANO 440 harvesters under the Skif TUCANO 440 trademark.

At the same time, the Ministry of Agrarian Policy also examined the projects of SKD assembly of harvesters manufactured by the U.S. company New Holland. Representatives of the ministry stated that with the help of these projects Ukraine could arrange assembly of up to 2,500 harvesters a year by 2017. Unfortunately, the plans went awry. The joint project with New Holland was lost “in the bowels” of the ministry and the KMBP manufactured at its own expense only four Skif TUCANO 440 models in 2013. While CLAAS received preliminary confirmation of the willingness to cooperate from German financial institutions, Ukraine gave no guarantees of the State Investment Company to attract a loan for continuation of financing of the joint project.

Admittedly, according to experts, the failure of the joint project with CLAAS may have another explanation. TUCANO 440 combines have a capacity of up to 10 kg/s, and, as it was mentioned, could be used for harvesting small areas. It is interesting that harvesters with insufficient capacity were also chosen for the recently announced joint Ukrainian-Belarusian project. The truth is that Palesse GS12 has a capacity of 12 kg/s, while Ukraine has an urgent need for combines with a capacity of more than 14 kg/s. At the same time, it should be noted that Gomselmash also manufactures Palesse GS16 harvesters with a capacity of 16 kg/s.

Obviously, both Belarusian and German manufacturers prefer to supply to the Ukrainian market the most popular and powerful models of equipment independently and agree to assemble through joint efforts only those types of equipment which in their homelands are no longer in demand and are gradually phased out from production at parent plants.

Meanwhile, Oliynik says the recipe for attraction of the location of production facilities was developed and successfully tested in many countries long ago. He believes foreign manufacturers will invest in production (without creation of some joint ventures) if they are granted essential tax benefits, namely, exemption from VAT on imports of capital goods. In particular, this applies to import of materials, components, assemblies and spare parts intended for their own production of agricultural machinery; import of machinery and equipment – for technical re-equipment of Ukrainian enterprises.

Moreover, provision of tax exemptions is a standard practice all over the world For example, there is a mechanism according to which income tax is not levied for the first five years after the launch of a project, for the following three years its rate is equivalent to 50% of the standard rate, for another two years the rate is 70% of the standard amount and the full amount of taxes is paid only starting with the eleventh year of operation.

It is also possible to consider an option of exemption of machine-building enterprises from land taxes for the period of implementation of the investment project. Such benefits (in various combinations) helped attract foreign investments into the production of agricultural equipment in China, Southeast Asia and Central Europe.

of the agreement of syndication with Financial Times Limited are strictly prohibited. Use of materials which refers to France-Presse, Reuters, Interfax-Ukraine, Ukrainian News, UNIAN agencies is strictly prohibited. Materials marked

of the agreement of syndication with Financial Times Limited are strictly prohibited. Use of materials which refers to France-Presse, Reuters, Interfax-Ukraine, Ukrainian News, UNIAN agencies is strictly prohibited. Materials marked  are published as advertisements.

are published as advertisements.